The financial impact of unexpected CNC machine failures extends well beyond simple repair costs in modern manufacturing environments. While technological advancements have reduced breakdown frequency, each incident now carries disproportionately higher consequences due to production losses and emergency repair scenarios. Although machine degradation remains an inevitable reality, implementing comprehensive maintenance protocols can significantly enhance both operational reliability and equipment longevity through continuous monitoring, scheduled component replacements, and early wear detection.

Many manufacturing operations fall into the counterproductive pattern of prioritizing short-term production targets over essential equipment maintenance, adopting a reactive "fix-when-broken" approach. This mindset often leads to cascading operational challenges including unplanned production stoppages, exponentially higher repair costs from accumulated damage, and potential workplace safety violations that can disrupt entire production schedules.

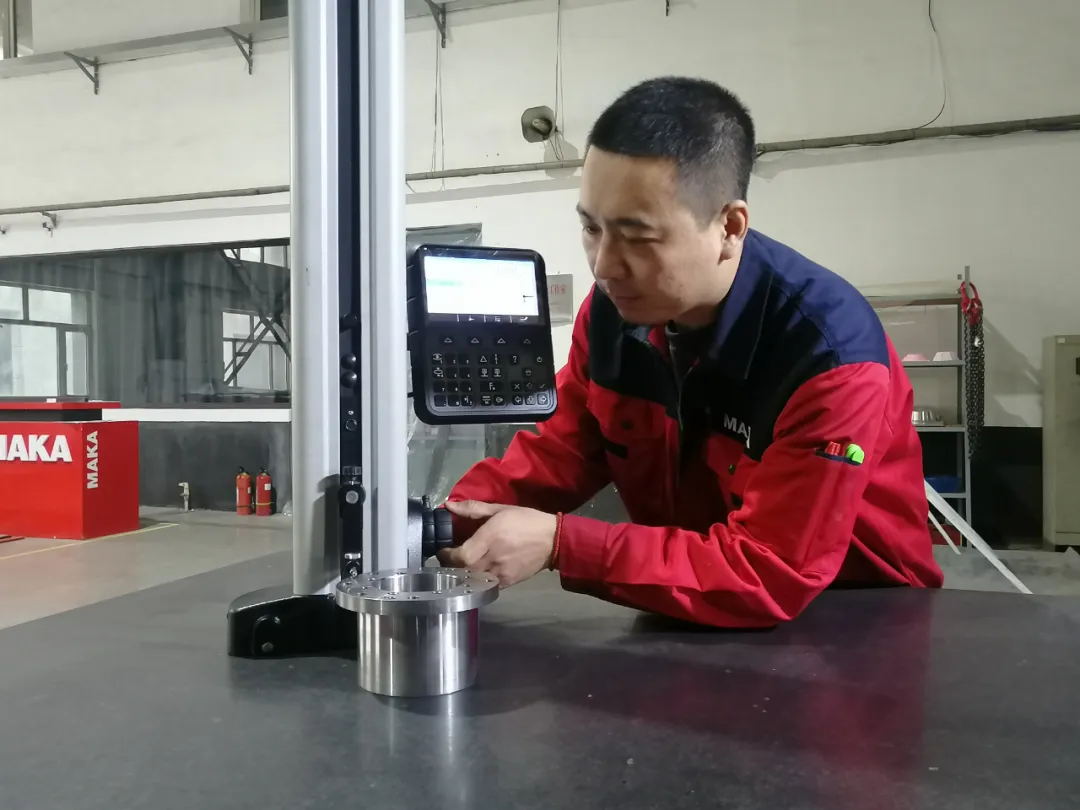

The evolution of maintenance strategies offers manufacturers multiple approaches to mitigate these risks. The most basic corrective maintenance method addresses issues only after failure occurs, which while suitable for non-critical equipment, carries inherent risks of complete production halts, secondary component damage, and regulatory non-compliance issues. More sophisticated preventative maintenance programs establish routine servicing intervals including lubrication procedures, precision calibration checks, and scheduled part replacements, proving particularly effective for operations with constrained maintenance windows and predictable equipment wear patterns.

The most advanced condition-based maintenance systems integrate real-time equipment monitoring with sophisticated data analytics and automated diagnostic tools. These systems provide substantial operational advantages through improved failure prediction accuracy, optimized maintenance scheduling, and reduced spare parts inventory requirements.

Transitioning from reactive to proactive maintenance philosophies typically yields measurable business improvements including substantial reductions in maintenance expenditures, fewer production disruptions, and extended equipment service life. By embracing these structured maintenance approaches, forward-thinking manufacturers can transform equipment care from a necessary cost into a genuine competitive advantage that supports sustainable operational excellence.

This comprehensive approach to CNC machine maintenance not only preserves capital equipment investments but also creates more predictable production environments where equipment reliability becomes a strategic asset rather than an operational variable. The cumulative effect of proper maintenance manifests in improved product quality, more consistent output, and ultimately, stronger financial performance across the manufacturing enterprise.

Customer service 1

Customer service 1 Customer service 2

Customer service 2