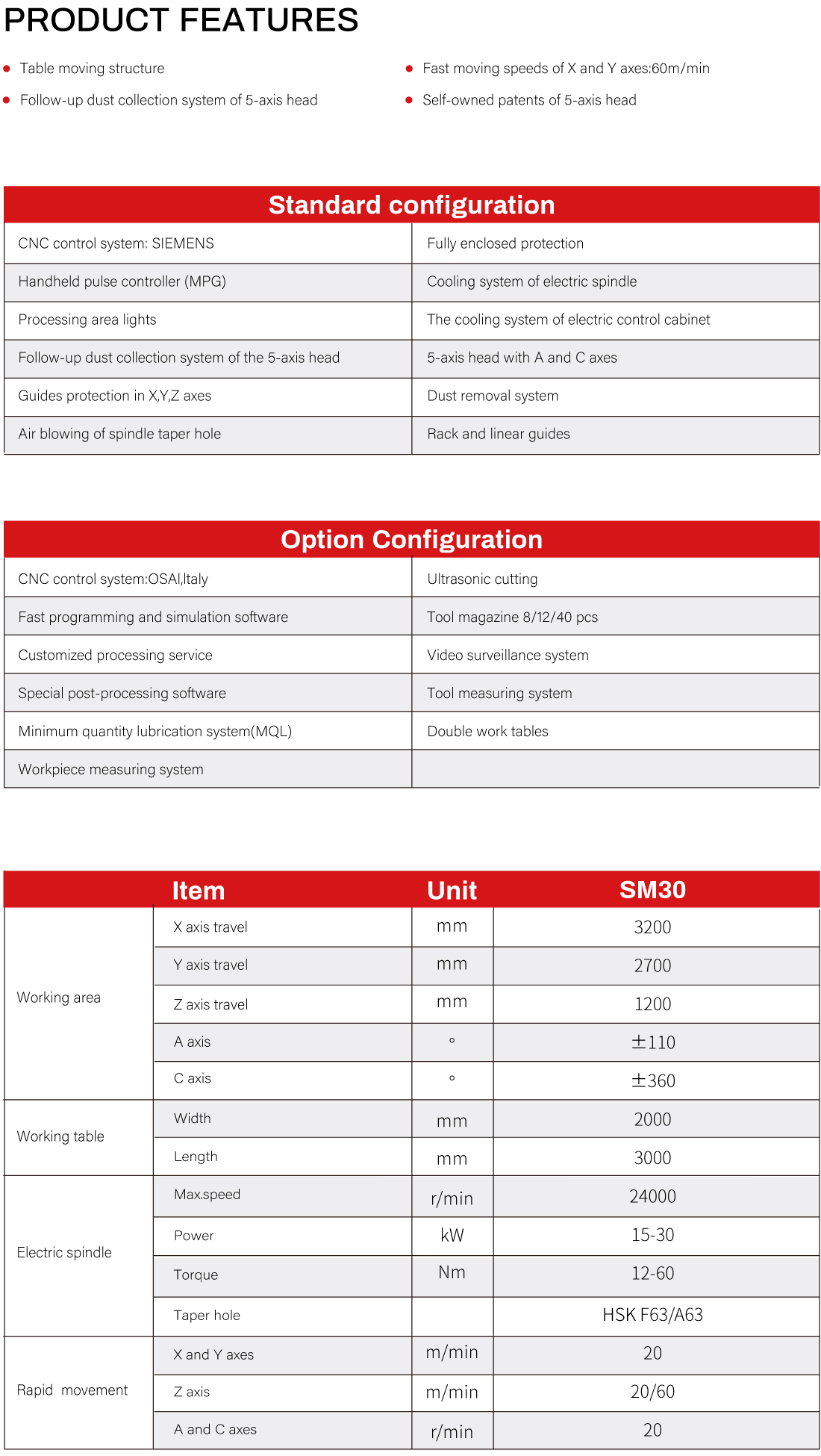

SM Series Showcase

Typical Applications: Composite Materials

MAKA

address:No. 19, Qianzhan Street, Dadong District, Shenyang

Telephone:0086-024-88258828

mailbox:sales@makacnc.com

Hotline

0086-024-89700158

work shift

from Monday to Friday

Company Office Number

0086-024-88258828