Product features

| ◎ Integral cast iron high rigidity structure | ◎ Two gear change headstock |

| ◎ Table transportable structure | ◎ High speed mechanical spindle |

| Standard configuration | |

control system :SIEMEN | Processing area lighting |

Single working tabl | Three colors alarm ligh |

Protection of working are | Mobile hand-held pulse generator |

Boring shaft/ Φ 110 | Bits cooling syste |

Liquid cooling system of five axes head | Hydraulic balance system in Z -axis |

Electric control cabinet cooling system | Grating ruler in B axis |

| Option Configuration | |

Control system : FANUC of Japan | Water outlet from spindle motor center (internal cooling |

Multi- pallet exchang | Three axis grating ruler in X,Y,Z axes |

| Enclosed protection | Automatic tool detection system |

Fixed spindle motor/boring spindle motor Φ130 | Automatic Workpiece inspection |

Automatic tool changer system: 40/60 | Video monitoring system |

| project | Unit | AH | |

| Workbench | width | mm | 1600-3000 |

| Length | mm | 2000-8000 | |

Working area | X-axis stroke ( front and rear travel of workbench ) | mm | 2000-8000 |

Y-axis stroke ( Up and down travel of spindle motor box ) | mm | 1700-3600 | |

Z-axis stroke ( front and rear travel of spindle motor ) | mm | 800/1250/1500 | |

| Worktable rotation (B axis) | ° | 360(0.001) | |

Spindle motor | speed | r/min | 4500-6000 |

| power | KW | 15-22 | |

| Taper hole | BT50 | ||

| Rapid movement | The X and Y axes | m/min | 15 |

| z-axis | r/min | 12 | |

Note: The technical parameters listed in the table are for reference only and are subject to change without prior notice..

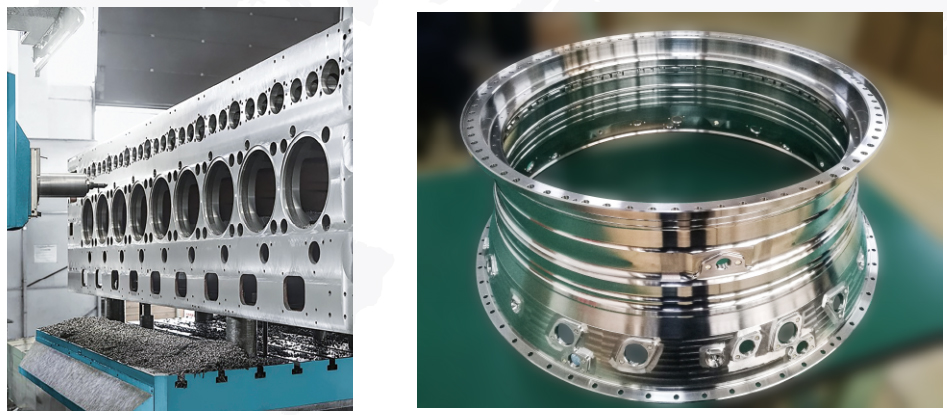

Typical application : AH Series

Parts machining of engine casings and engine box for plane

Customer service 1

Customer service 1 Customer service 2

Customer service 2